Pinchrollers

It was a long and tedious way to offer you the pressure rollers in their current quality.

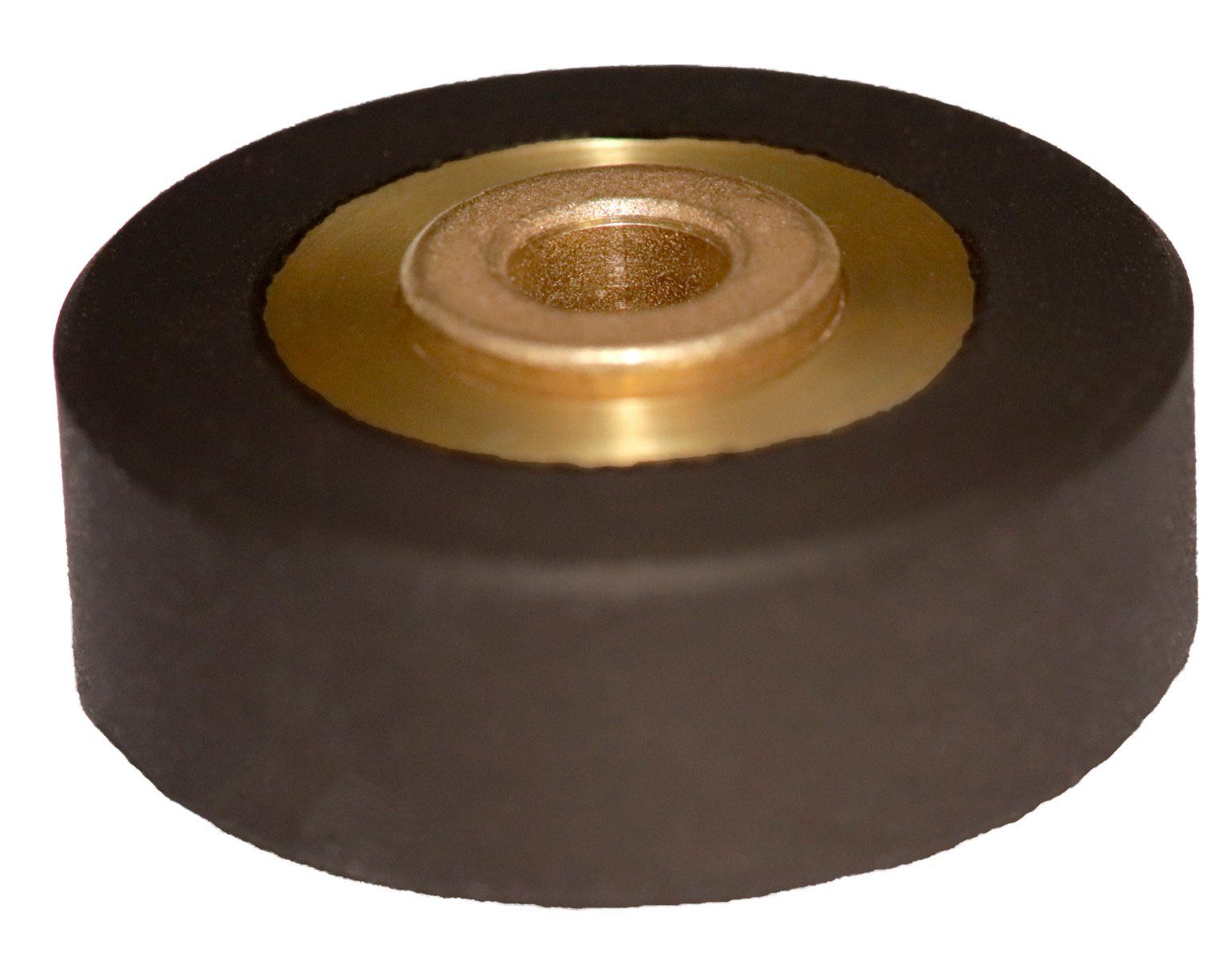

Not only the materials of the rubber used (we have never used polyurethane) and the bearing, also the production and the necessary steps had to be found and worked on first.

So the final step is the round grinding of the rubber and the rubbing of the sintered bushing. Beforehand, the edges of the rubber are chamfered at 45 °.

All our pinch rollers receive the right sintered bearing oil and are therefore maintenance-free.

Furthermore, we can offer suitable accessories for the pressure rollers such as sintered bearing oil, Teflon sliding washers, circlips and copper discs.

Revox A77

with 11 mm axle length

Revox B77

with 9 mm axle length

Pinchroller B77

also suitable for Revox A700, PR99 MKI, MKII, MKIII, C270, C274 and Studer A67, B67, A807, A810.

With us only real rubber is used. After vulcanising and pressing the sintered bearing into the brass bushing, the round bevel and the 45 ° chamfer take place.

Only then can we meet the specifications of Studer and Revox!

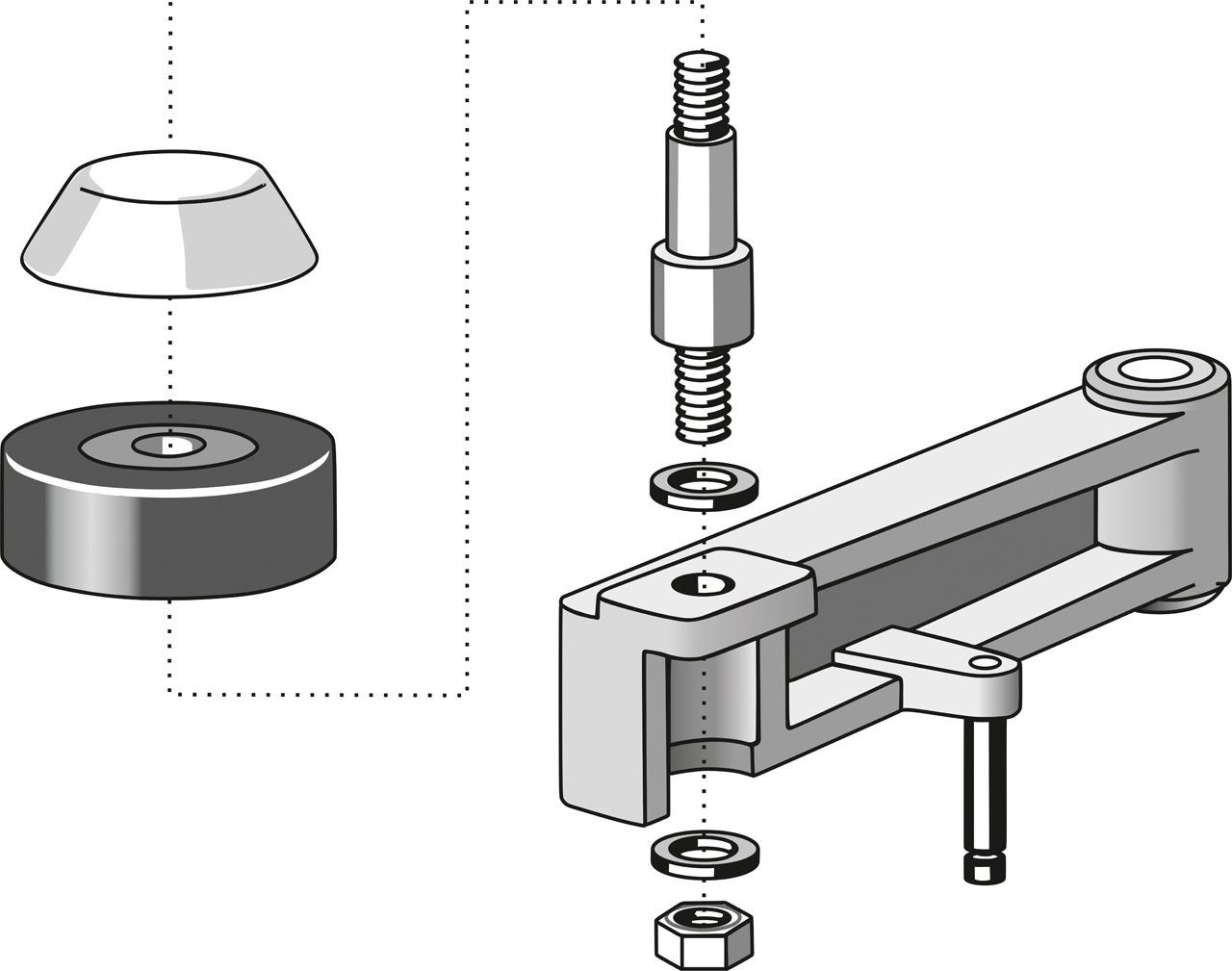

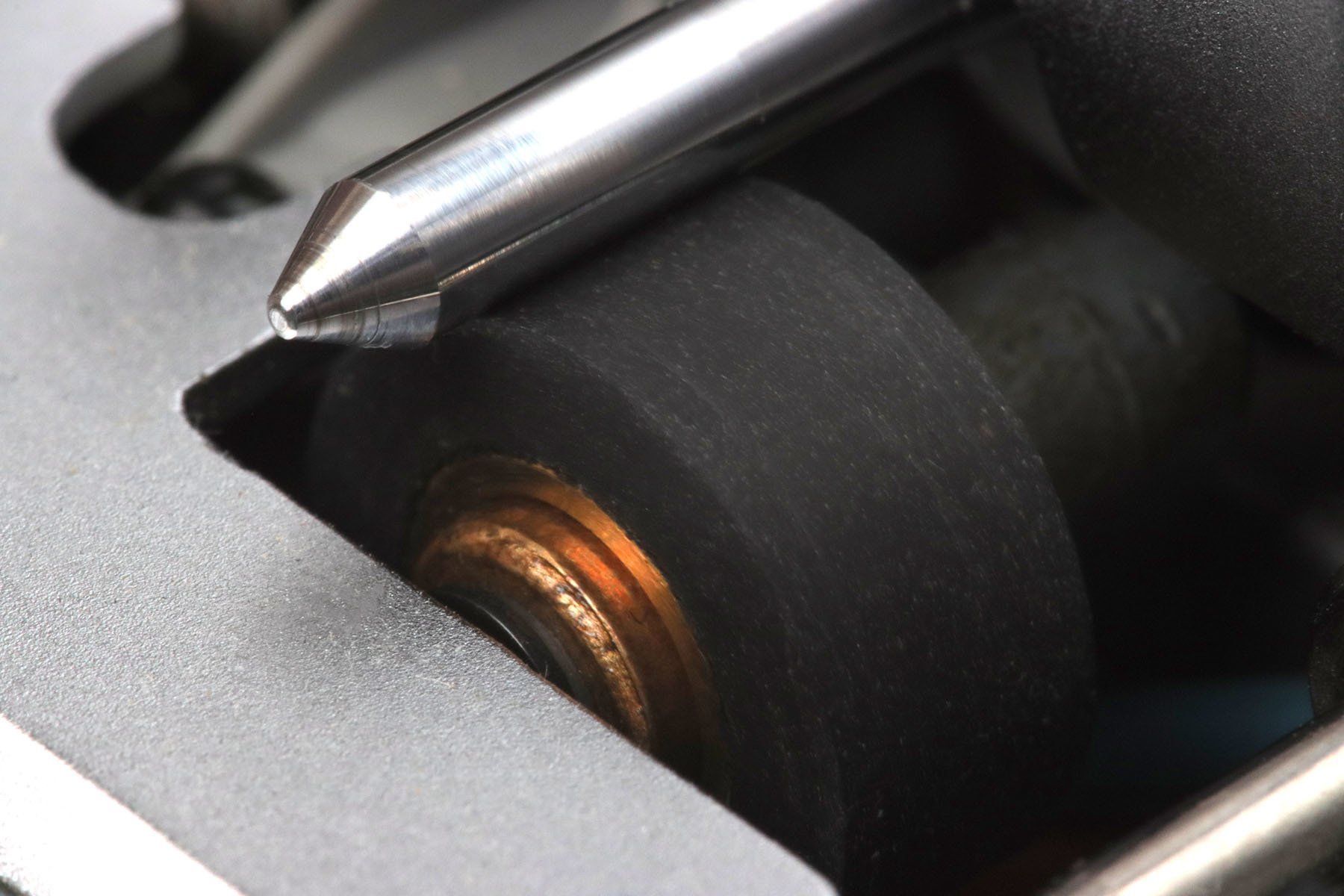

Installation in B77

First comes the copper disk on the axle, then a Teflon disk, then the pinch roller, another Teflon disk and only then the cover!

We have already experienced the most amazing things, all the discs below, all the above, sometimes completely without discs and also with too many discs, then the roller clamps nicely! Often only the copper disc is missing, then the pinch roller has too much play on the axle and the belt can not be properly guided!

Again, we offer suitable accessories such as the stainless steel countersunk screw M3 x 8 mm

the teflon discs (sliding washers) 5 x 10 x 0.25

Copper disc 5 x 8 x 0.15

and so on.

Revox A700

Studer A807

Studer A810

Revox B710, Studer A710

Danger!

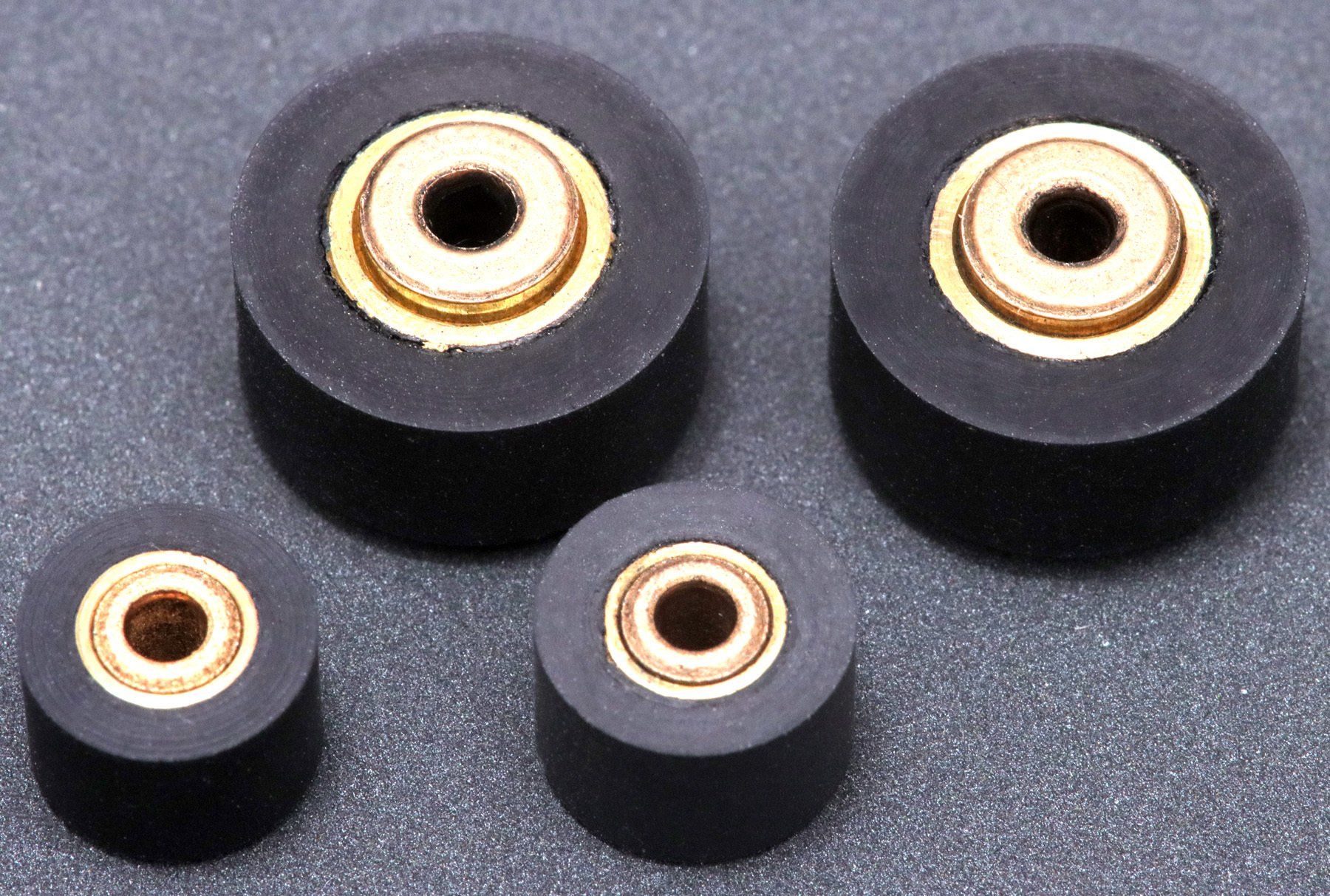

With the tape deck Revox B710, Studer A710 there are differences in the diameter of the pressure rollers!

The first version has the pinch rollers with two different sizes.

The pressure roller on the left has a diameter of 8.0 mm and the right pressure roller has 8.6 mm.

The second version has two pinch rollers, each with a diameter of 13.0 mm.

Again, our rubberized pinch rollers have a sintered bronze bearing and are ground in the last step and the bushing rubbed.

Revox B710, Revox B215,

Studer A721

Pinchrollers

in our shop

Here you will find the precision pinch rollers for many

Studer and Revox devices