Studer A101 Hybrid modul

Why we do it?

The wildest stories about this primitive hybrid circuit Studer A101 are rampant on the Internet!

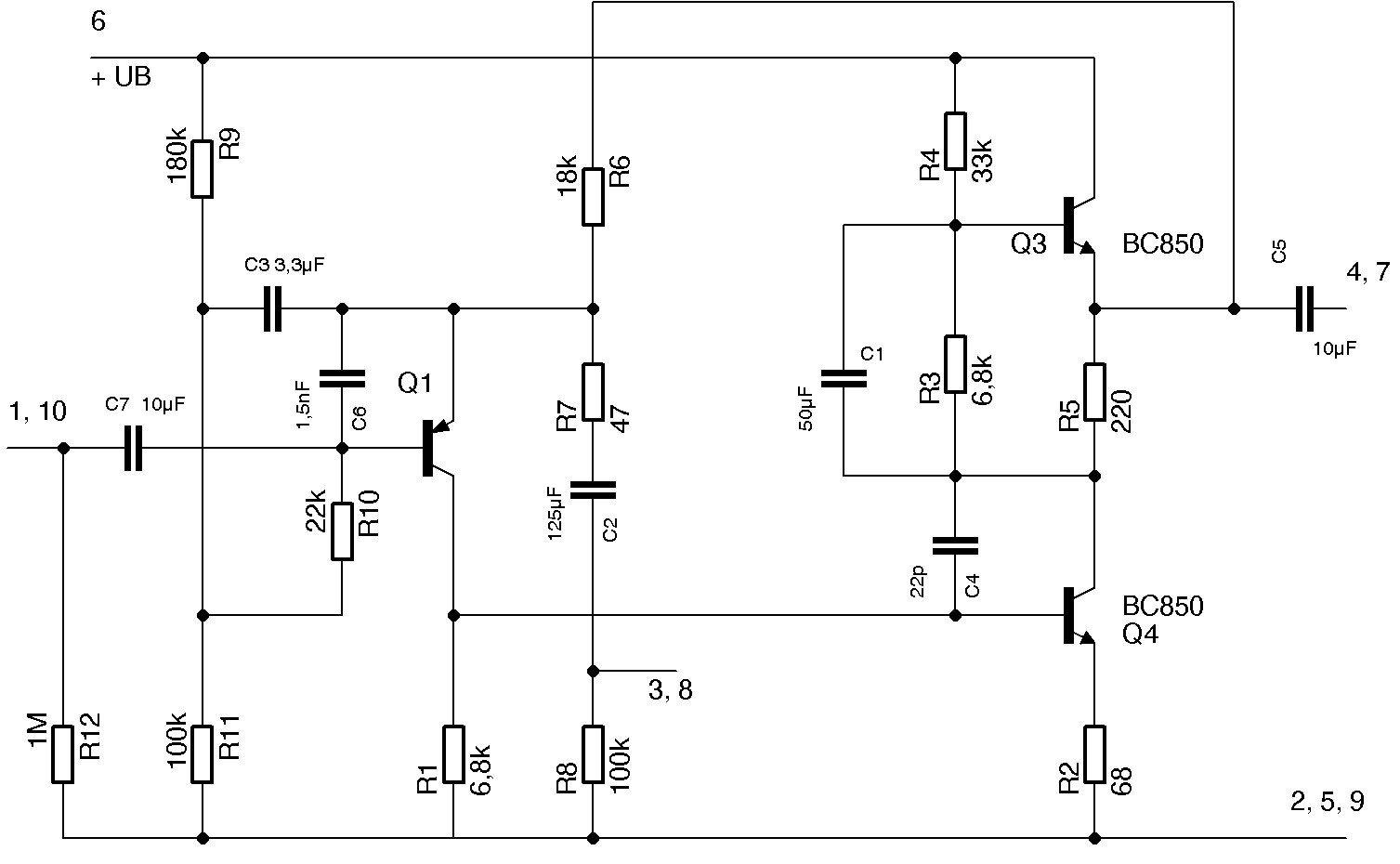

The circuit consists of a simple differential input amplifier, without a current source, current mirror or other, and a driver output stage.

The circuit consists of 4 transistors, 5 resistors and the original with 1 Tantal capacitor with 10µF. Didn´t sound like rocket science!

With the Studer A101, the negative feedback must be set externally via the connections X2-5 and X2-8.

New soldering process

Components are cooled and soldered for only one second!

It is actually claimed that the transistors are cooled during soldering and that the soldering per pin only lasts a maximum of one second. Hats off, we're amazed at building blocks!

Quote:

which are processed by complex manufacturing technology to avoid thermal stress on the components during soldering, e.g. B. the Transistors soldered in a cooled device, the resistors at a distance of 5mm wire length.

All components are soldered by hand with a maximum Soldering time of 1 sec per solder joint.

The success of the effort is that the components used retain their excellent technical data and thus the module receives the best possible quality.

The prints are fully professionally manufactured,

Quote end:

We as electronic engineers have learned:

1) that the solder joint (the soldering eye and the connection of the component) is preheated with the soldering iron for one or one and a half seconds.

2) Then the solder (with flux in the soul) is entered into the solder joint. It is not the soldering iron that is wetted with the solder, but the soldering eye and the connecting wire of the component. This can take a second or two!

3) after three to four seconds after the solder has run well, the soldering iron is removed and the heat input into the soldering point is ended.

If you hear now, there will only be a maximum of one second per solder joint - fingers away - you will only get cold solder joints, ice cold solder joints!

Such prints are not professionally made, it has nothing to do with professional soldering - that's just Murks!

There are many, many ways to make the circuit better.

Instead of the emitter resistor with 43.2 kOhm, a high-quality, low-noise current source with LED, transistor and resistor could be realized.

A current mirror consisting of two further transistors could be installed in the collector branch.

Finally, in the power supply, the input stage and the output stage have two separate positive operating voltage inputs, each with a block capacitor.

It is a mystery to start here with the thermal stress during soldering ????

Furthermore, the Studer A62, Studer B62 and Studer A80 do not only sound so good because low-noise hybrid modules were used! If this position had been so crucial, one could have used other things in 1970. The entire concept of the tape recorders is responsible for the high quality, since the hybrid modules A101 are only involved to a very limited extent. Nevertheless, we do not want to lower the quality of the devices and have thought about it!

Wired

Why?

If you really want to do something to minimize noise, why wired components?

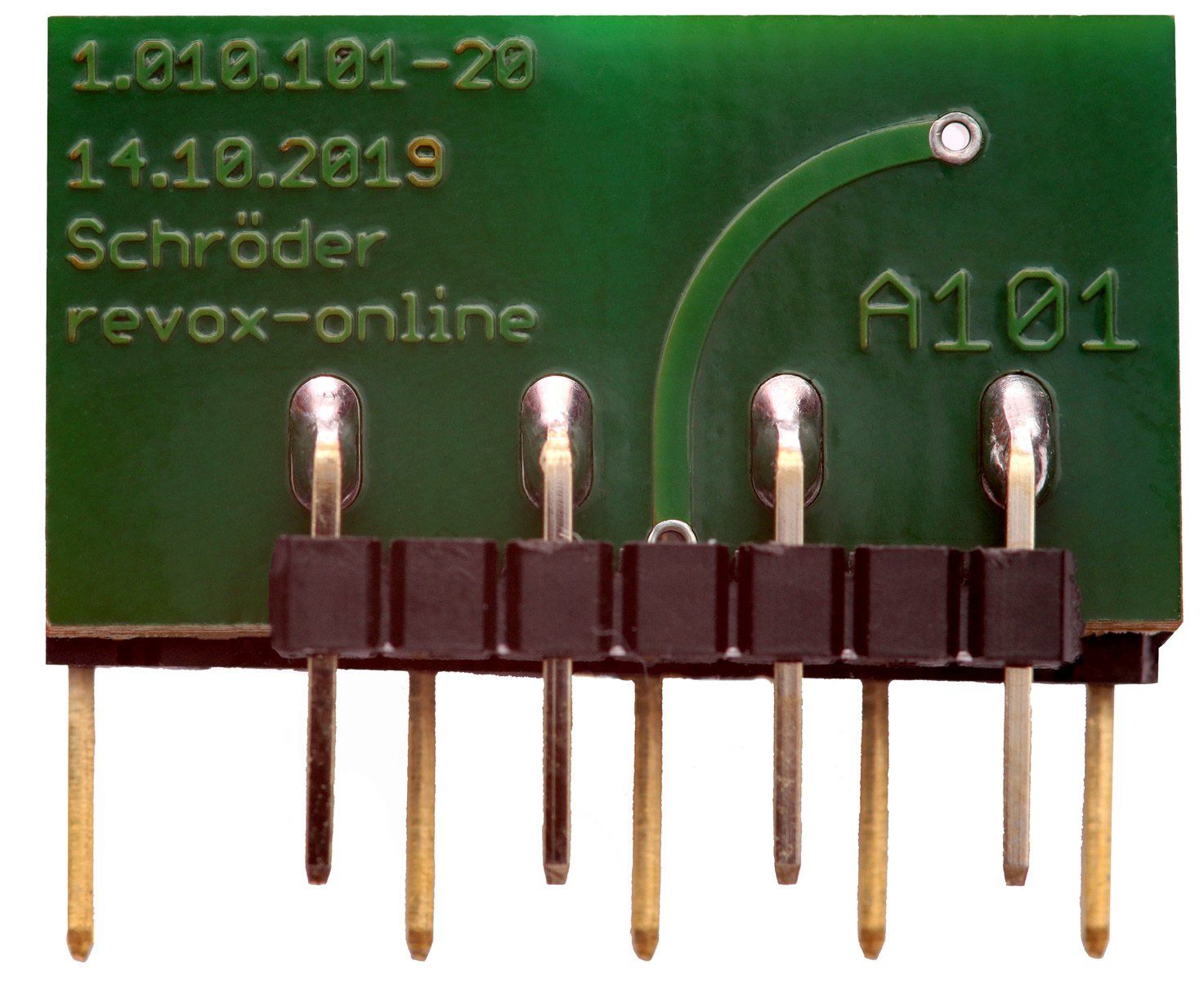

SMD components have major advantages not only because of the smaller space requirement. The absence of the long iron wires, which usually contain iron, is also an advantage. The layout itself is always better if it is thought through. It leads to shorter paths and better routing!

Another advantage of SMD technology: The soldering temperatures are specified by the programmed soldering furnace and are set and controlled for an optimal soldering result with minimal component stress.

We used the option of separate operating voltage and blocked both amplifier stages separately with one capacitor each!

As here with the Studer A80 Reproduce PCB, everything fits 100%. Wherever the original hybrid module is installed, our equivalent circuit also fits, no components have to be bent, the noise is minimized. The double row pin header ensures a stable mechanical hold of the circuit boards.

low noise!

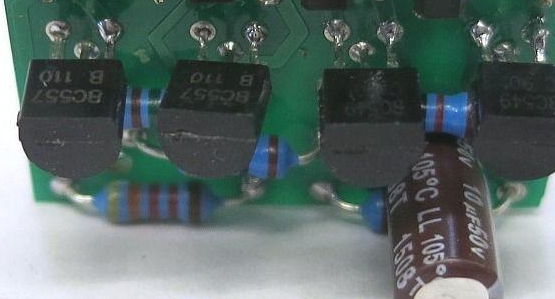

BC557

since when?

Another provider offers a version with low-noise transistors, but equips the BC557 in the input stage! You need to know that there is a group of PNP transistors starting with BC556 to BC560. Only the BC559 and BC560 transistors are low-noise. With the NPN transistors, only the BC549 and BC550 are low-noise. We use the low-noise SMD derivatives BC850 and BC860.

We have never read and seen so much nonsense that we decided to take countermeasures here!

Further information on differential amplifiers, current mirrors and current sources can be found in the standard work on semiconductor circuit technology from Tietze-Schenk-Gamm:

Current sources and current mirrors can be found from page 287 and from page 339 the differential amplifier will follow!

Studer A101 in our shop

Here you will find the Studer A101 hybrid amplifier module for Studer A62, B62, A80 Studer mixing consoles and so on.