Power supply board B750

new development

Whether it brings something tonally?

Well, due to the somewhat strange wiring of the power supply, our hands are tied when it comes to optimization. That was also the problem when developing the toroidal transformer of the Revox B750. We would like to have the windings in relation here

optimized for the losses.

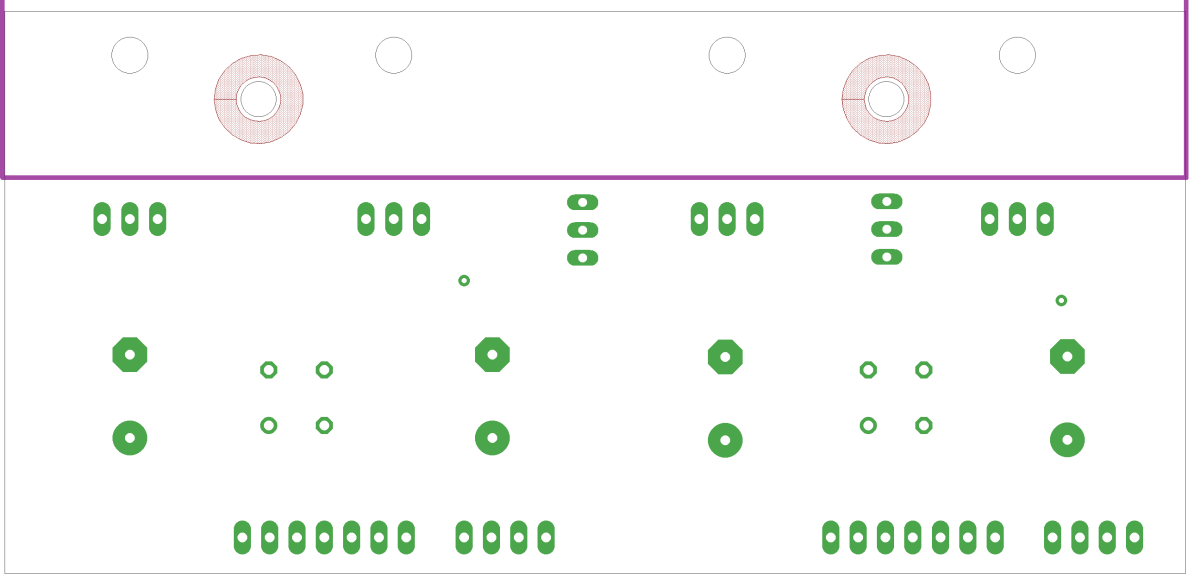

However, we did make a few improvements to the new circuit board. We have that Power supply designed with audiophile in mind. The AC input voltages each have an interference suppression capacitor, the rectifiers each have 4 additional capacitors, parallel to the diodes. The charging filter capacitors each have a bypass capacitor with 10µF, there are no more electrolytic capacitors. The voltage regulators are less noisy. The traces are considerably shorter and are now 70 µm thick instead of the standard 35 µm!

basics

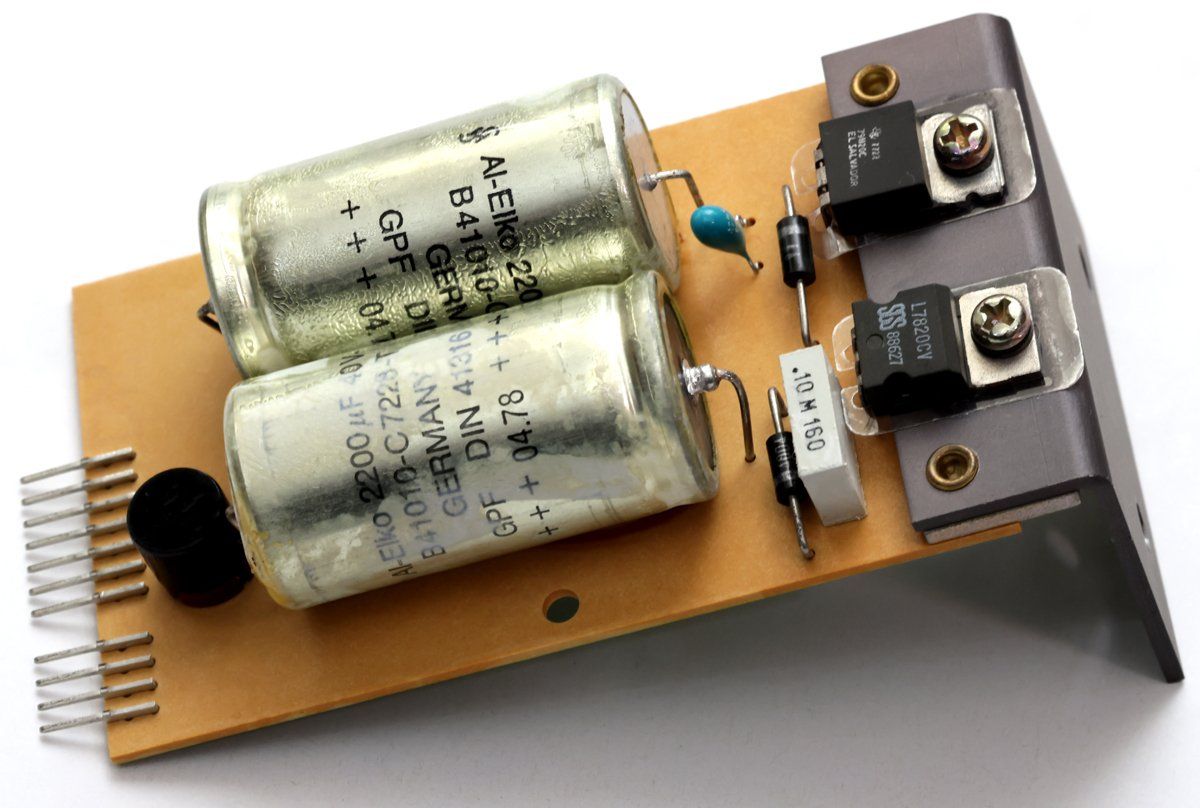

radial and axial capacitors

When we see that axial electrolytic capacitors (the layout is designed for axial electrolytic capacitors with the long traces and the connections of the axial electrolytic capacitors are im electrolytic capacitor body always attached on both sides) can be replaced by cheaper radial electrolytic capacitors with even longer connection wires!

To put it mildly - it makes us sick!

Especially since the axial electrolytic capacitors can be bought everywhere and we have the axial electrolytic capacitors manufactured according to our specifications! We don't understand how to screw up a Revox B750 amplifier or other Revox Studer devices because of a few euros! With a first-class, high-quality amplifier, this is not the way to go!

The new layout of the new power supply board is designed by us for radial electrolytic capacitors!

the technique

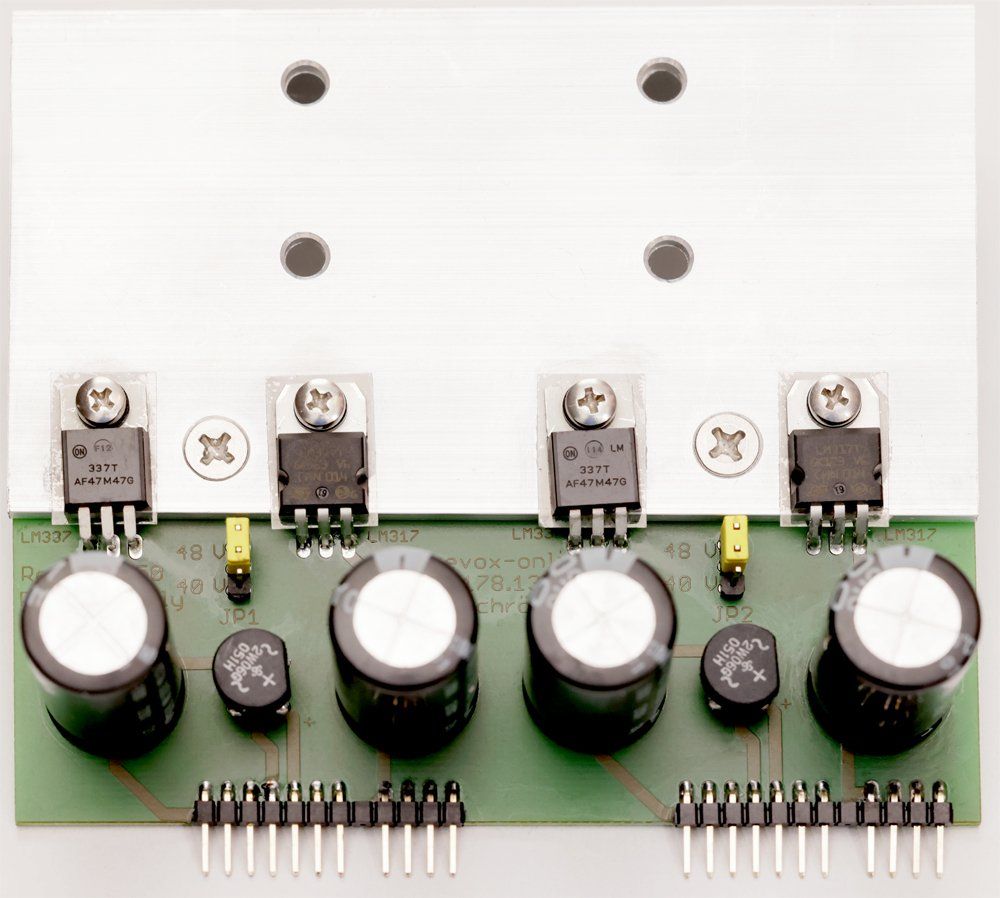

LM317 and LM337

voltage regulator

The well-known voltage regulators we use are not modern. But we wanted to do without exotics. Who knows how long the exotics will be produced and

the availability is one of those things.There will be neither an LDO (Low Drop Out) at the very high input voltage nor 3, 5 or even7 amperes required!

noise

The output noise of the voltage regulator used is just as good as with the 0.003% times the output voltage

LT 1085 and significantly better than the fixed voltage regulators of the 78xx or 79xx series.we

have been using the regulators LM 317 and LM 337 in our power supply repair kits since 2007.

The cooling

Because use space properly!

We have significantly increased the effective cooling surface and can screw on another heatsink if needed. This does not bring any advantages in terms of sound, but a colder environment protects the components all around from aging too quickly. Especially the electrolytic capacitors will thank you! As already mentioned - we cannot prevent the enormous power loss of the power supply unit of the amplifier.

Advantages of the new cooling

Which version?

MK I or MK II

Version from S no. 8501

Starting with serial number 8501, both power supplies were combined on one printed circuit board. In addition, the voltage was increased from 40V to 48V and the attachment was also changed. Our new power supply board fits both the 40V version and the 48V version. Simply set the jumpers to the 40V or 48V position.

for all Revox B750

The new power supply circuit board fits all Revox B750 amplifiers and can be adjusted accordingly on site. You just have to move the two jumpers up towards the heatsink for the 48V variant (as in the photo) or both jumpers down for the 40V variant. The attachment also fits both versions of the amplifier.

oddities

AUA

With the best of intentions! How to reuse only the old regulators for a new circuit design?Leaded components - okay, electrolytic caps - okay, but the UA79GU or UA78GU, not even for a try! If you don't understand the technology or the way the engineers at Revox think... ...it's not always easy!

Then the description of the strange circuit says something about improved shielding! Where is the shield please?

45 years of standstill

What a waste of space! We use the space for significantly better cooling. We wanted to replace the power supply board years ago. Still had circuit boards from repair stocks so there was no compulsion to make the new circuit board. In the meantime, however, we can no longer finish a Revox B750 because we lack the power supply!

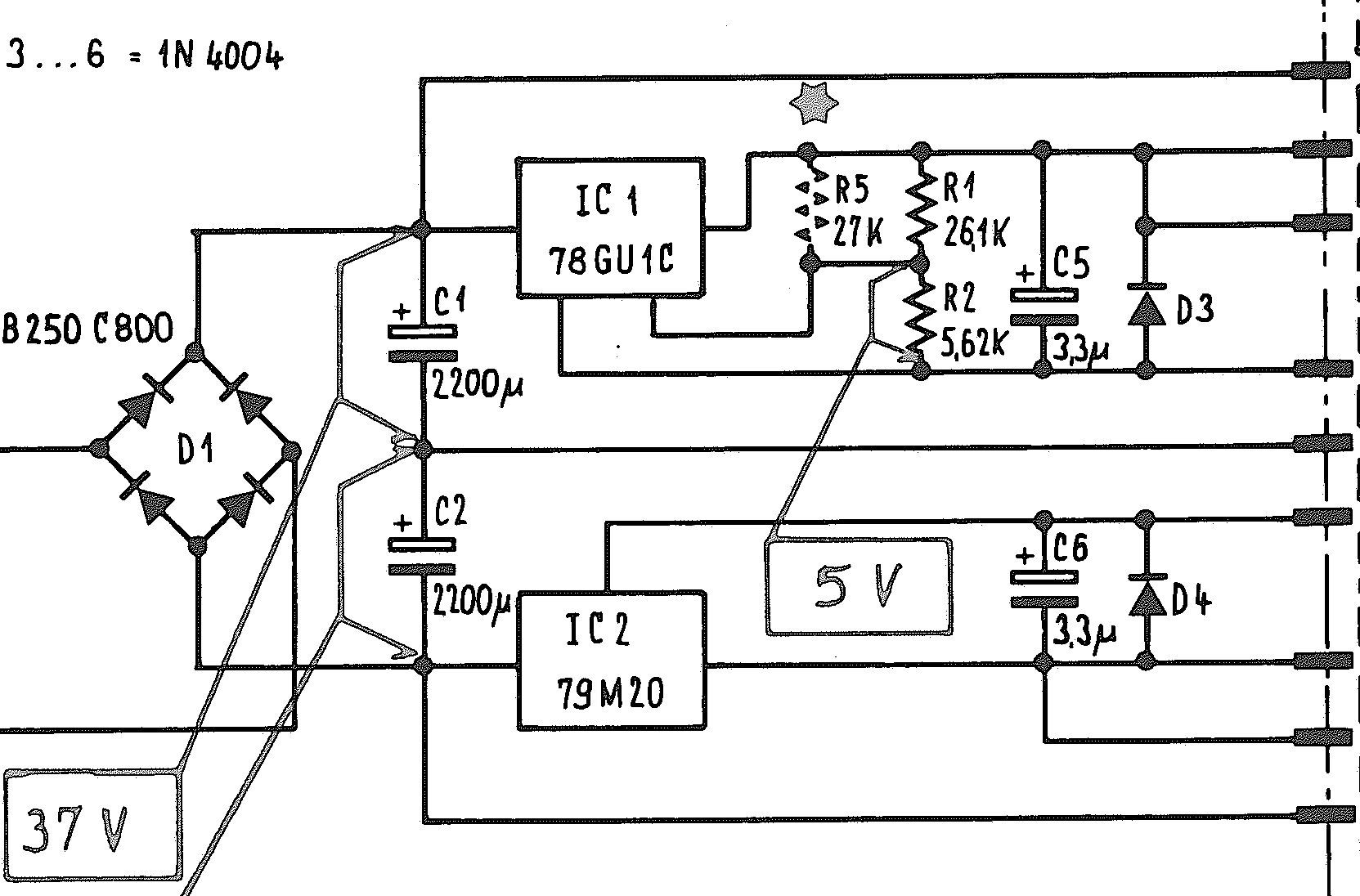

circuit diagram

Why did Revox choose this path?

Why the 20V via a negative regulator and the -20V via a positive regulator? It's a good thing that the /- 40 V or /- 48 V was not taken from the device ground because the controllers only tolerate a maximum input voltage of 40 V. If these controllers were related to the device ground, the input voltage would have been well over 70 V. The 37 V via the electrolytic capacitors is already borderline!

brand new power supply boards

for all Revox B750 can be found in our shop